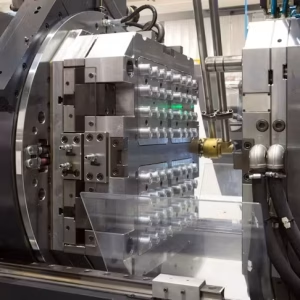

Every manufacturing facility knows the frustration of injection molding defects. Parts come out warped, incomplete, or with visible flaws that make them unusable. These common injection molding defects create headaches for production managers who need consistent quality output.

The reality is that injection molding process complexity makes defects almost inevitable without proper control. Small changes in temperature, pressure, or timing can turn perfect parts into expensive scrap.injection molding defects show up in different ways – some affect appearance while others compromise structural integrity.

Most problems trace back to three main areas: process settings that aren’t quite right, mold design issues, or materials that weren’t prepared correctly. Each category brings its own set of challenges.

How Injection Mold Defects Actually Form

When plastic pellets get heated and pushed into mold cavities, hundreds of variables come into play. Injection speed might be too fast, injection pressure could drop unexpectedly, or melt temperature varies from shot to shot. Any of these changes can create problems.

Molten plastic doesn’t behave the same way every time. Hot material flows differently than cooler material. Thick sections cool slower than thin ones. The flow of molten plastic through gates and runners creates turbulence that can cause defects downstream.

Today’s injection molding operations deal with tighter tolerances and more complex geometries than ever before. What worked fine for simple parts might fail completely on intricate designs. Temperature swings that seemed minor suddenly become critical when dealing with molded parts that have strict requirements.

When Material Flow Goes Wrong

Flow Lines and Surface Streaking

Flow lines are those wavy patterns that show up on part surfaces, usually near where material enters the mold. These streak marks happen when molten plastic doesn’t flow evenly through the cavity. Different flow speeds create temperature variations that leave visible evidence of the problem.

The fix often involves tweaking injection speed until flow becomes more consistent. Mold temperature also matters – too cold and material starts hardening before the cavity fills completely. Gate location makes a big difference too.

Silver Streaking and Moisture Issues

Silver streaking looks exactly like it sounds – silvery lines that radiate out from injection points. This happens when moisture gets trapped in the plastic material. Pre-drying the plastic properly eliminates most of these issues, but many facilities skip this step or don’t do it thoroughly enough.

Humidity in the plant can affect material even after drying. Storage containers that aren’t sealed properly let moisture creep back in. The solution involves both proper drying procedures and better material handling throughout the process.

When Parts Don’t Fill Properly

Short Shot Problems

Short shot happens when molten plastic can’t reach every corner of the mold cavity. Parts come out incomplete – missing features, thin spots, or sections that just didn’t fill at all. Usually this traces back to injection pressure being too low for the job.

Other causes of short shots include runners that get blocked with debris, poor venting that traps air, or mold temperature that’s wrong for the material being used. Sometimes slowing down helps by giving material more time to flow, but more often increasing pressure does the trick.

The best approach combines better gate design with improved venting and making sure there’s enough material available when the machine calls for it.

Warp and Dimensional Control

Warp shows up as twisted or bent parts that don’t match the intended shape. This happens when thick sections cool differently than thin ones, creating stress that pulls the part out of shape. Keeping wall thickness consistent throughout the design prevents most warping issues.

Good cooling system layout makes a huge difference. Mold temperature control needs to be precise – even small variations can cause problems in complex parts with intricate geometries.

Surface Problems That Ruin Parts

Sink Marks Formation

Sink marks look like small dents or depressions on what should be flat surfaces. They typically show up in thicker sections where the inside material shrinks as it cools, pulling the outer surface inward. The part looks fine until you notice these annoying dimples.

The real culprit is usually inadequate packing pressure during cooling. Here’s what actually works:

- Bump up packing pressure and hold it longer

- Keep wall thickness more uniform across the part

- Make sure cooling happens efficiently

- Watch melt temperature carefully

Surface Delamination Issues

Surface delamination creates thin layers that literally peel off the part like bad paint. Contaminated resin causes most of these problems – sometimes mixed with too much release agent or incompatible materials that don’t want to stick together.

Prevention comes down to cleaner processing. Handle materials properly, use release agents sparingly, and keep mold temperature where it needs to be for good bonding.

When Different Flow Streams Meet

Weld Line and Knit Lines

Weld line problems happen when two or more flow fronts come together but don’t bond properly. These knit lines create weak spots that can break under stress – plus they’re often visible on the finished part. Temperature differences between the converging flows usually cause the bonding failure.

Getting this right means:

- Raising melt temperature so material stays workable longer

- Tweaking injection speed and pressure for better flow

- Moving gates around to avoid problem convergence points

- Picking the right resin that flows well at reasonable temperatures

Parts with holes, inserts, or complex shapes almost always deal with weld lines somewhere. It’s just part of the geometry.

Jet Formation Control

Jet defects create those squiggly snake-like patterns you see on part surfaces. This happens when molten plastic shoots into the cavity too fast without touching the walls first. The flow of plastic creates these distinctive marks that weaken the part.

Slowing down injection speed usually fixes this. Better gate design can also help by giving the material a more controlled entry path.

Internal Problems You Can’t Always See

Vacuum Voids and Air Pockets

Vacuum voids are air bubbles trapped inside parts where they shouldn’t be. Poor venting systems and rushing the injection process create perfect conditions for trapped air pockets. These internal defects weaken parts in ways that might not show up until the part fails in service.

Here’s what actually prevents them:

- Design better venting into the mold

- Control injection speed so air can escape

- Increase the injection speed gradually rather than hitting full speed immediately

- Make sure materials are prepared correctly

Burn Marks and Overheating

Burn marks show up as dark streaks or spots on part surfaces. Material gets too hot and actually starts degrading, leaving these telltale signs. Trapped air pockets make this worse because compressed air gets extremely hot during injection.

Troubleshooting means backing off on temperatures, checking that venting works properly, and not pushing injection speed beyond what the system can handle cleanly.

Getting Your Process Dialed In

Parameter Control Methods

Effective solutions for injection molding defects require patience and systematic testing. Injection pressure, temperature, and timing all interact with each other – change one and the others might need adjustment too. Common defects usually have multiple causes working together, which makes troubleshooting tricky.

| Defect Type | First Thing to Try | Key Setting |

| Flow Lines | Increase injection speed | Injection Speed |

| Short Shot | Bump up pressure | Injection Pressure |

| Warp | Check cooling balance | Mold Temperature |

| Sink Marks | Extend hold time | Hold Pressure |

Quality Control Integration

Modern injection molding operations use sensors and monitoring systems that track everything in real time. When conditions start drifting, operators can catch problems before bad parts start coming out. Defects often happen because someone missed a gradual change in conditions.

Injection molders who track their data consistently can spot patterns that predict trouble. Temperature trends, pressure variations, and cycle time changes all tell a story about what’s happening inside the mold.

Material and Design Factors

Molding Material Selection

Molding material choice affects everything downstream. Some resin types are forgiving while others require precise conditions to work properly. Understanding what each material needs helps prevent problems before they start.

Molding process settings that work great for one material might be completely wrong for another. Storage conditions matter too – some plastics absorb moisture from the air and need special handling.

Mold Design Optimization

Injection mold design determines whether defects can be avoided or are built into the process. Gate location, runner size, and cooling layout all affect how well parts turn out. Good venting eliminates trapped air problems that create other issues.

Mold cavities need consistent temperature control across the entire surface. Parting line quality and surface finish affect final part appearance significantly.

Real-World Applications

Automotive Manufacturing

Automotive parts can’t fail in service, so injection molded part quality becomes critical. Defects can reduce safety margins and create liability issues. Most automotive suppliers have strict quality systems that catch problems early.

Electronics and Consumer Products

Electronic enclosures need precise fits and good surface finish. Surface defects affect both function and appearance – scratches can interfere with connectors while flow lines look unprofessional on consumer products.

Systematic Troubleshooting Approach

Potential injection molding defects need methodical diagnosis to fix properly. Common molding defects share similar root causes, making systematic analysis essential for efficient problem-solving.

Defects in injection molded parts typically fall into four main categories: material problems, wrong process settings, mold design issues, or equipment that needs maintenance. Injection molding defects caused by each category require different approaches to resolve.

| Problem Area | Typical Issues | Where to Start |

| Material | Moisture, contamination | Check drying, storage |

| Process | Temperature/pressure off | Review parameter logs |

| Mold Design | Poor venting, gates | Evaluate tooling |

| Equipment | Worn parts | Inspect, maintain |

Injection molding services companies increasingly use predictive analytics to spot problems before they create scrap. Machine learning systems analyze process data and flag when conditions drift toward trouble. This proactive approach reduces waste significantly.

Molding components benefit from preventive maintenance schedules. Worn screws, barrels, and molds gradually create more defects over time. Regular maintenance prevents gradual quality degradation.

The National Institute of Standards and Technology (NIST) research on injection molding energy consumption demonstrates how process optimization supports both quality and sustainability goals. This work shows the importance of balancing efficiency with defect prevention.

Conclusion

Common injection molding defects challenge every manufacturing operation, but understanding their causes makes prevention possible. Success comes from combining proper mold design, careful process control, and consistent material handling.

The best results happen when design engineers, toolmakers, and production teams work together from the start. Companies like Tuowei Prototype demonstrate how advanced injection molding design and process optimization minimize defect risks through integrated approaches.

Long-term success depends on continuous improvement, proper training, and investment in monitoring technology. These elements create manufacturing systems that consistently produce quality parts while minimizing waste and rework costs.

Frequently Asked Questions

What causes most injection molding defects? Most injection molding defects result from improper process parameters including temperature, pressure, and timing control. Material preparation and mold design also play critical roles in defect prevention.

How can short shot defects be prevented? Short shot prevention requires adequate injection pressure, proper gate sizing, and effective venting. Maintaining optimal mold temperature ensures complete cavity filling during the injection cycle.

Why do weld lines form in molded parts? Weld line formation occurs when separate flow fronts meet without adequate bonding temperature. Higher melt temperature and optimized injection speed help prevent this structural defect.

What role does mold temperature play in quality? Mold temperature controls material flow, cooling rates, and final part dimensions. Proper temperature control prevents warping, improves surface finish, and ensures consistent part quality.

How do modern systems detect defects automatically? Advanced monitoring systems use sensors, machine vision, and statistical analysis to identify defects often missed by visual inspection. Real-time data enables immediate process corrections.

References

- National Institute of Standards and Technology. “Characterizing Energy Consumption of the Injection Molding Process.” NIST Publications, 2013.

- Wikipedia. “Flow mark.” Wikipedia, The Free Encyclopedia, 2023.

- Wikipedia. “Injection moulding.” Wikipedia, The Free Encyclopedia, 2025.

- Society of Plastics Engineers. Technical publications on injection molding defect prevention.

- American Society for Testing and Materials (ASTM). Standards for plastic materials and injection molding processes.